What is UID?

In 2003 the Dept. of Defense specified a 2D barcode for encoding serial numbers on every significant asset. There is an operational and tactical advantage in tracking resources. This leads to better field support to the front lines and cost savings. Today that UID barcode is mandated and enforced.

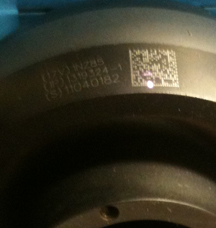

The UID code looks like this.

UID on Tungsten F/A 18 Gyro

UID marks can be placed on tags or they can be directly marked onto the part. Direct Part Marking is an area that Applied Light can help.

MicroScan UID Verifier - Click on the Image to see a representative Validation Report - Showing an "A" which is Great!!

What information is on the Mark?

The requirement, MIL-STD 130N describes different levels of information. Generally Direct Part Marks require the strict Construct II form. Construct II requires a CAGE code (or DUNS number), a Product code (usually the part number), and a Serial Number. Bear in mind that the UID mark is a complete mark in its entirety so the actual serial number when considered along with the CAGE code and the part number is unique to your organization.

We can apply that mark correctly and we can Verify and Validate the mark so that your parts are accepted by the contract administrator.

Barcodes , there are so many and we do most of them. One of the most unique and difficult are 2D barcodes such as UID, but our capabilites are not limited to that.

We mark linear barcodes such as Code 39 or Code 25 directly on parts and also on labels.

Focus on UID style Marking

UID is also known as MIL-STD 130 and is a requirement presently for many products sold to the DOD, NASA and certain other US Government agencies. The UID is shorthand for “Unique Identification” and is always a 2D mark. There are a number of specific requirements for this mark, the most important are:

- The UID mark is intended to survive for the lifetime of the product that carries it. - A UID mark is attached to the part, either as a label or engraved directly into it. - The UID format meets the MIL-STD 130 specification - A fully compliant UID is not only marked on the part, but is registered with the DOD. - The registration ensures that the UID is in fact unique. No two marks are the same.

How do we fit into this?

We mark labels or directly onto the part. We also perform a service called Verification and Validation. This means that we read the mark with a MicroScan camera. The camera software then determines if the mark meets two criteria. First, the software checks that the mark is valid and it carries the information in the correct format. Second, the software scores the image to determine mark image quality. The camera scores the image from A –to- F. All successful UID marks must meet a “B” score or better. (Ours typically score an “A”.)

When we are done, your parts are marked and the scored results accompany them back to you on a CD. You can give your customer this scored result so the parts may be registered for acceptance by the DOD.

Other Barcodes

There are many other barcode types and we do most of them. A common requirement is Code 39 linear bars and we can place these on your parts.

Materials we Mark for UID

Many materials will mark, but not all will mark with enough contrast to meet the UID requirements. For example, black anodized aluminum will mark well, but green anodized aluminum can miss the verification requirement due to low contrast. In steel and clear anodized aluminum we use TherMark, a black powder, to apply UID marks with sufficient contrast. TherMark bonds to the base material and is dark to create good contrast. Other choices are tape (see tesa vs. 3M below) or black nickel plating, or black anodized plating, or similar coatings that provide good contrast. These choices allow for steel, stainless steel, aluminum and some plastics such as ABS or polycarbonates.

tesa(TM) vs. 3M for label material

There is a common callout for tesa(TM) tape on UID contracts. tesa is a German company which produces a two-part co-extruded acrylic tape, generally black over white. This tape is durable and carries a legible mark when lasered. 3M is an American company which produces a comparable product at a significant cost savings over tesa. The materials are functionally identical, but tesa is slightly thicker than the 3M equivilent and is sometimes preferred. Otherwise, 3M tape can be substituted for tesa. Other label materials are permitted for UID marks, just follow the basic rule that the mark must last the lifetime of the part. Small parts, too small to carry a UID on them, are allowed to be marked on the packaging.

Firearms.All firearms acquired by the US DOD must carry a UID mark. We can apply the UID directly to the weapon or supply a tag.