What is Contract Marking?

Sometimes referred to as Service Bureau work, contract marking is using Applied Light as part of your process. Our laser facility saves you capital and labor expense and puts our experience and specialized knowledge to work on your products.

Hastalloy Marks with Sparks

Why use Outside Vendors?

Applied Light is a business dedicated to laser processing. We use several different types of lasers because no single laser type is best for every job. We develop the process, identify and use the correct equipment to meet your specifications and have the correct staff to meet your budget and your timeline.

When your task grows such that it makes sense to bring it in house, our experience can direct your capital to best meet your specific need.

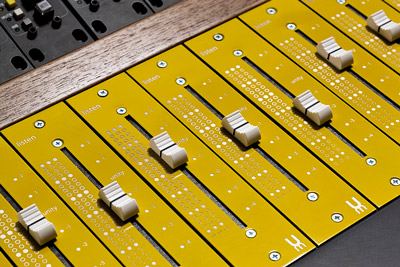

UM Project Soundboard

Soundboard Left Side

Laser Marking add style to function

Materials We Mark

StainlessSteel Paint Filled Steel Chromate Plated Steel

Typically we mark metal such as Steel, Aluminum, Brass, Silver, Titanium, Hastalloy, Stainless Steel, and others.

We also mark Plastics including ABS, Delrin (black) , HDPE, Polycarbonate or Lexan, Noryl and others. Not all plastics are good candidates for marking with examples such as PVC and teflon release toxic gasses when marked or cut. Others, like HDPE, will mark but without the crisp look common to laser marking.

The plastic color is very important as well. For example nylon marks well in both natural and black, but the natural color has no contrast and needs to be filled with a color to show up.

We also mark wood, glass, stones, semiprecious stones and paper.

Serialization

We serialize products all the time. You indicate the starting number and we sequence through your parts. If there are non-sequential numbers we can use a text or Excel(TM) list of serial numbers.

We serialize with barcodes and Human Readable Information (HRI). Barcode serialization often includes HRI as well. Serialization is also done with 2D barcodes such as UID for military applications.

Depth of mark

Marking is done in layers. For most jobs a single laser mark repeat will suffice. Other requirements need multiple repeats to drive the depth. We will mark .0005" - .002" deep typically and .015” - .018” deep by request. Deep marking is more expensive.

Artwork

Most marking is done with vectors - lines, so we prefer .pdf or .dxf or .ai type files for that. We can convert .tif or .jpg files into the best art for lowest cost marking. When we convert files there is an artwork fee, such as $25 or $50 for a file. In some cases the cost can be higher.

The typical .jpg file incorporates a gaussian diffusion at the edges and this makes .jpg files excellent for larger images typically found in wood and leather, but not recommended for metal marks. When marking metal we generally convert these to .pdf, .ai or similar vector files described above. Discuss your artwork with us to see how it might best be used.

Firearms

We are licensed to handle most firearms both rifles and handguns. Our FFL permits us to work with firearms but not explosives, silencers or automatic weapons. In some cases we will work on automatic weapons and silencers, but a permitted person must be present at all times.

Please be aware that when you are dropping off serialized firearms or controlled parts you must be licensed to receive them back

Restorations

We work with an internationally recognized expert in the field of automobile chrome restorations. This company receives valuable trim parts that are corroded, bent or deformed. Many of these parts have makers marks on them and the restoration process will remove these important marks.

Other applications include Plaques, Trophies, Plates and other wood or metal parts.

We carefully photograph and document the original parts prior to restoration and when the parts are prepared, we laser the makers marks back into the now perfect pieces and some results are found on winners of international competitions.

Fonts and images.

Any of our many fonts in our system are available to you. A list of these fonts is seen here . If your needs are specific we will source a font for you at cost.

Our image collection is always expanding, however many of our images are covered by copyright restrictions. A sampling of our public images can be seen here.

Estimating Costs

We usually charge a setup fee for every job. Setup is typically $17.50, but can be $25 or $35 if the tooling effort is significant. The cost to mark is based on time of the mark including handling. A majority of our production marking is under $0.95 ea. and most jobs are under $5 per piece. To date our most expensive single part has been $750, and the customer was very pleased with the result and the value.

Packaging requirements also affect the cost. Individual bagging or wrapping will add cost where bulk packaging will probably not. Many projects use "egg crates" to keep parts protected but make handling easy. We use these where possible to keep the parts protected but reduce handling time. This method, along with loose bulk packing will keep your costs to a minimum.